Metal Roofing Panels

nap-Clad, Tite-Loc, Snap-On, Redi-Roof, PAC-150, and PAC T-250 are metal roofing panels by Petersen

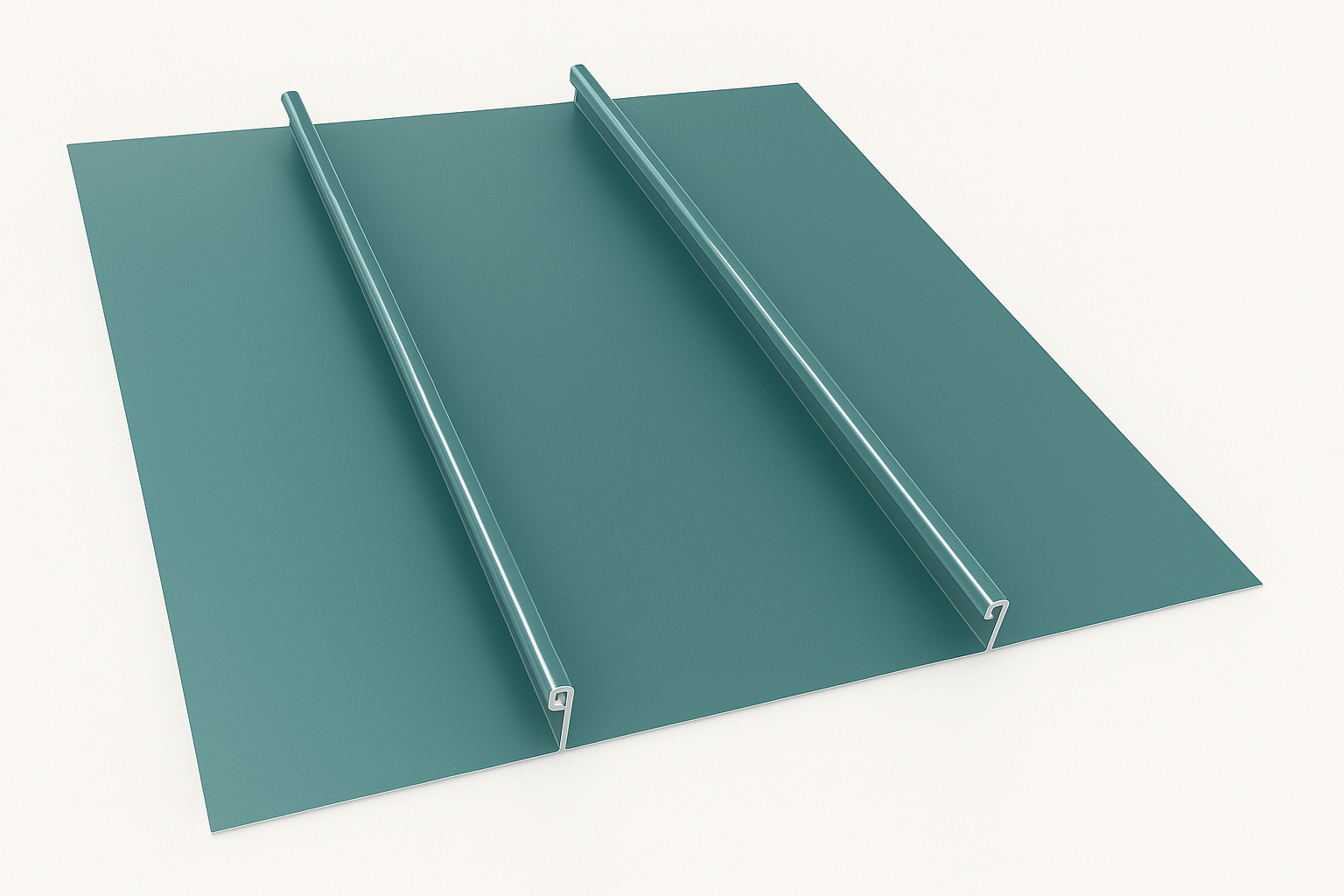

tite-loc

Features & Benefits

Pencil ribs (stiffening beads) are available only by request

35-year non-prorated finish warranty

Maximum factory-produced panel length is 64’ (check w/factory for longer lengths)

Weathertightness warranty available

Tite-Loc panels deliver a balance of structural strength and architectural appeal, featuring exceptional flatness and optional enhanced weather resistance. Offered in lengths ranging from 4 to 64 feet, they include a 2-inch leg height for mechanical seaming. Designed for use over a variety of substrates, these panels require a minimum roof pitch of 1/2:12. Available in both steel and aluminum, Tite-Loc panels can also be curved to meet specialized design needs.

Trim

All flashing and trim shall be fabricated by manufacturer or qualified fabricator. Flashing shall be PAC-CLAD aluminum (.032 – .063 gauge as specified) or PAC-CLAD steel (24 gauge or 22 gauge as specified). A 35-year non-prorated finish warranty can be supplied covering finish performance. Vinyl masking is recommended on all fabrication applications where extra handling is expected. NOTE: The strippable film must be removed immediately after installation.

Installation

Tite-Loc Plus panels are intended for use in architectural and structural roofing. Substrates may include 5/8” (min.) plywood, nailboard insulation or equal with an underlayment of ice and water shield applied horizontally from eave to ridge. Other substrates may include metal decking, purlins or rigid insulation in conjunction with bearing plates. A minimum 1/2:12 pitch is required. Contact Petersen for further assistance with projects details.

Snap-on standing seam

Designed with concealed fastener systems and optional curved profiles, these panels deliver reliable structural performance for a wide range of applications—from architectural to industrial roofing. Available in both steel and aluminum, they are compatible with multiple substrates, roof slopes, and a broad selection of color finishes.

Snap-Clad

Features & Benefits

High Density Polypropylene Cores

Water and impact resistant options.

Easily cut-to-size in the field (or from the manufacturer)

Panel composition warranty (10 years)

Snap-Clad metal roofing panels offer aesthetic appeal and strong performance. Made in continuous lengths, they feature a 1-3/4” leg height, interlocking design, and concealed fasteners for durability. The panels come with factory-applied sealant for weather resistance and can be installed on various substrates. A 35-year finish warranty is available.

Seaming

Tite-Loc panels require the use of mechanical seamers. When seaming panels on slopes greater than 6:12, caution must be exercised to prevent seamer slippage and resulting finish scratches that may void the warranty. Seamers are available along with hand crimpers and other tools through D.I. Roof Seamers, which is the only supplier of this equipment approved by Petersen Aluminum.

Installation

Tite-Loc panels are intended for use in architectural and structural roofing. Substrates may include 5/8” (min.) plywood, nailboard insulation or equal with an underlayment of ice and water shield applied horizontally from eave to ridge. Other substrates may include metal decking, purlins or rigid insulation in conjunction with bearing plates. A minimum 1/2:12 pitch is required. Contact Petersen for further assistance with projects details.

tite-loc Plus

Features & Benefits

Pencil ribs (stiffening beads) are available only by request

35-year non-prorated finish warranty

Maximum panel length varies by facility. Consult rep for details.

Weathertightness warranty available

Tite-Loc Plus panels offer a premium blend of structural durability and architectural style, ensuring excellent flatness and reliable weather resistance. Featuring a 2-inch leg height for mechanical seaming, these panels are available in multiple lengths and material options. Trim components are precisely fabricated from PAC-CLAD aluminum or steel for a cohesive finish. Installation requires approved substrates and a minimum roof pitch of 1/2:12 for optimal performance.

Snap-On standing seam roof panels are ideal for roofing, mansard, and fascia applications, designed for installation over waterproofed substrates with a minimum 3:12 pitch. Factory roll-formed in continuous lengths, they offer superior flatness. Metal panels require specified flashing and trim, with installation using non-penetrating clips. Curved panels are suitable for barrel vaults, with a minimum 9’ radius.

Features & Benefits

Ideal for transition roofs

Pencil ribs available

35-year non-prorated finish warranty

Panel lengths up to 35’

Curved Panels

The 1” Snap-On standing seam panel can be curved to a concave or convex radius, with a minimum radius of 9’. This panel is ideal for barrel vaults and entrance ways. Curved panels must be installed over a waterproofed solid substrate.

Installation

Snap-On panels shall be installed over solid decking (5/8” plywood, nailboard insulation or equal) with an underlayment applied horizontally from eave to ridge. Panels shall be fastened using Petersen nonpenetrating clips, fastening on 18” centers (max.). Minimum slope at 3:12 pitch. Consult a local architect or engineer for requirements of local codes and conditions.

Snap-on batten

Snap-On panels are well-suited for roofing, mansard, and fascia applications, designed for installation over a solid, waterproofed substrate with a minimum slope of 3:12. Factory roll-formed in lengths ranging from 4 to 35 feet, these panels ensure precision and consistency. Flashing and trim components are crafted from PAC-CLAD aluminum or steel to match. Installation requires non-penetrating clips and a horizontally applied underlayment for optimal performance.

Features & Benefits

Ideal for transition roofs

Pencil ribs available

35-year non-prorated finish warranty

Panel lengths up to 35’

Trim

All flashing and trim shall be fabricated by manufacturer or qualified fabricator. Flashing shall be PAC-CLAD aluminum (.032 – .063 gauge as specified) or PAC-CLAD steel (24 gauge or 22 gauge as specified). A 35-year non-prorated finish warranty can be supplied covering finish performance. Vinyl masking is recommended on all fabrication applications where extra handling is expected. NOTE: The strippable film must be removed immediately after installation.

Installation

Snap-On panels shall be installed over solid decking (5/8” plywood, nailboard insulation or equal) with an underlayment applied horizontally from eave to ridge. Panels shall be fastened using Petersen nonpenetrating clips, fastening on 18” centers (max.). Minimum slope at 3:12 pitch. Consult a local architect or engineer for requirements of local codes and conditions.

High Snap-On Standing Seam Panel

Snap-On panels are perfect for roofing, mansard, and fascia applications, engineered for installation over solid, waterproofed substrates with a minimum roof pitch of 3:12. Offered in continuous lengths from 4 to 35 feet, these panels deliver outstanding flatness and clean lines. Custom-fabricated trim and flashing ensure a seamless finish, backed by a 35-year limited warranty. Installation requires solid decking, a properly applied underlayment, and non-penetrating clips for secure attachment.

Features & Benefits

Ideal for transition roofs

Pencil ribs available

35-year non-prorated finish warranty

Panel lengths up to 35’

Trim

All flashing and trim shall be fabricated by manufacturer or qualified fabricator. Flashing shall be PAC-CLAD aluminum (.032 – .063 gauge as specified) or PAC-CLAD steel (24 gauge or 22 gauge as specified). A 35-year non-prorated finish warranty can be supplied covering finish performance. Vinyl masking is recommended on all fabrication applications where extra handling is expected. NOTE: The strippable film must be removed immediately after installation.

Redi-Roof Standing Seam

Snap-Clad metal roofing panels offer aesthetic appeal and strong performance. Made in continuous lengths, they feature a 1-3/4” leg height, interlocking design, and concealed fasteners for durability. The panels come with factory-applied sealant for weather resistance and can be installed on various substrates. A 35-year finish warranty is available.

Features & Benefits

Available with or without offsets

Labor-saving one-piece design

Pencil ribs available

35-year non-prorated finish warranty

Panel lengths up to 45’

Trim

All flashing and trim shall be fabricated by manufacturer or qualified fabricator. Flashing shall be PAC-CLAD aluminum (.032 – .063 gauge as specified) or PAC-CLAD steel (24 gauge or 22 gauge as specified). A 35-year non-prorated finish warranty can be supplied covering finish performance. Vinyl masking is recommended on all fabrication applications where extra handling is expected. NOTE: The strippable film must be removed immediately after installation.

Installation

Redi-Roof panels shall be installed over solid decking with an underlayment applied horizontally from eave to ridge. Panels shall be fastened using Petersen nonpenetrating clips, fastening on 18” centers (max.). Minimum slope at 3:12 pitch. Consult a local architect/engineer for requirements of local codes and conditions.

PAC-150 90° Seam

PAC-150 metal roofing panels deliver a sleek architectural appearance paired with reliable structural performance. Featuring a 1.5-inch leg height, these panels are mechanically seamed in the field for long-term durability. Offered in a variety of widths and materials—including 24-gauge steel and aluminum—they can be curved for design flexibility and are suitable for roof slopes as low as 1:12. Proper installation requires seamers, with equipment available through approved suppliers.

Features & Benefits

35-year non-prorated finish warranty

Available in four pan variations; smooth, striated, pencil rib or flat rib. Check locally for panel condition availability

Maximum panel length of 64’ when factory or shop-formed but virtually unlimited when field-formed

Mechanically seamed in the field to 90°

Weathertightness warranty available

Curved Applications

The PAC-150 panels can be curved to a minimum radius of 20’. Curving can be done in the field or at the factory depending on the radius and length of the roofing panel. For details about curving capabilities, please contact the Acworth, Ga., or Annapolis Junction, Md., factories.

Seamers

PAC-150 panels require the use of mechanical seamers. When seaming panels on slopes greater than 6:12, caution must be exercised to prevent seamer slippage and resulting finish scratches that may void the warranty. Seamers are available along with hand crimpers and other tools through D.I. Roof Seamers, which is the only supplier of this equipment approved by Petersen Aluminum.

PAC-150 180° Seam

PAC-150 roofing panels provide a balanced blend of structural reliability and architectural style. Offered in a range of widths and materials, including steel and aluminum, they are engineered for low-slope applications down to 1:12. The panels require mechanical field seaming and are available with curving options to meet specific design needs. Manufactured in Georgia, Maryland, and Arizona, freight charges may vary based on location.

Features & Benefits

35-year non-prorated finish warranty

Available in four pan variations; smooth, striated, pencil rib or flat rib. Check locally for panel condition availability

Maximum panel length of 64’ when factory or shop-formed but virtually unlimited when field-formed

Mechanically seamed in the field to 180°

Weathertightness warranty available

Curved Applications

The PAC-150 panels can be curved to a minimum radius of 20’. Curving can be done in the field or at the factory depending on the radius and length of the panel. For details about curving capabilities, please contact the Acworth, Ga., or Annapolis Junction, Md., factories.

Seamers

PAC-150 panels require the use of mechanical seamers. When seaming panels on slopes greater than 6:12, caution must be exercised to prevent seamer slippage and resulting finish scratches that may void the warranty. Seamers are available along with hand crimpers and other tools through D.I. Roof Seamers, which is the only supplier of this equipment approved by Petersen Aluminum.

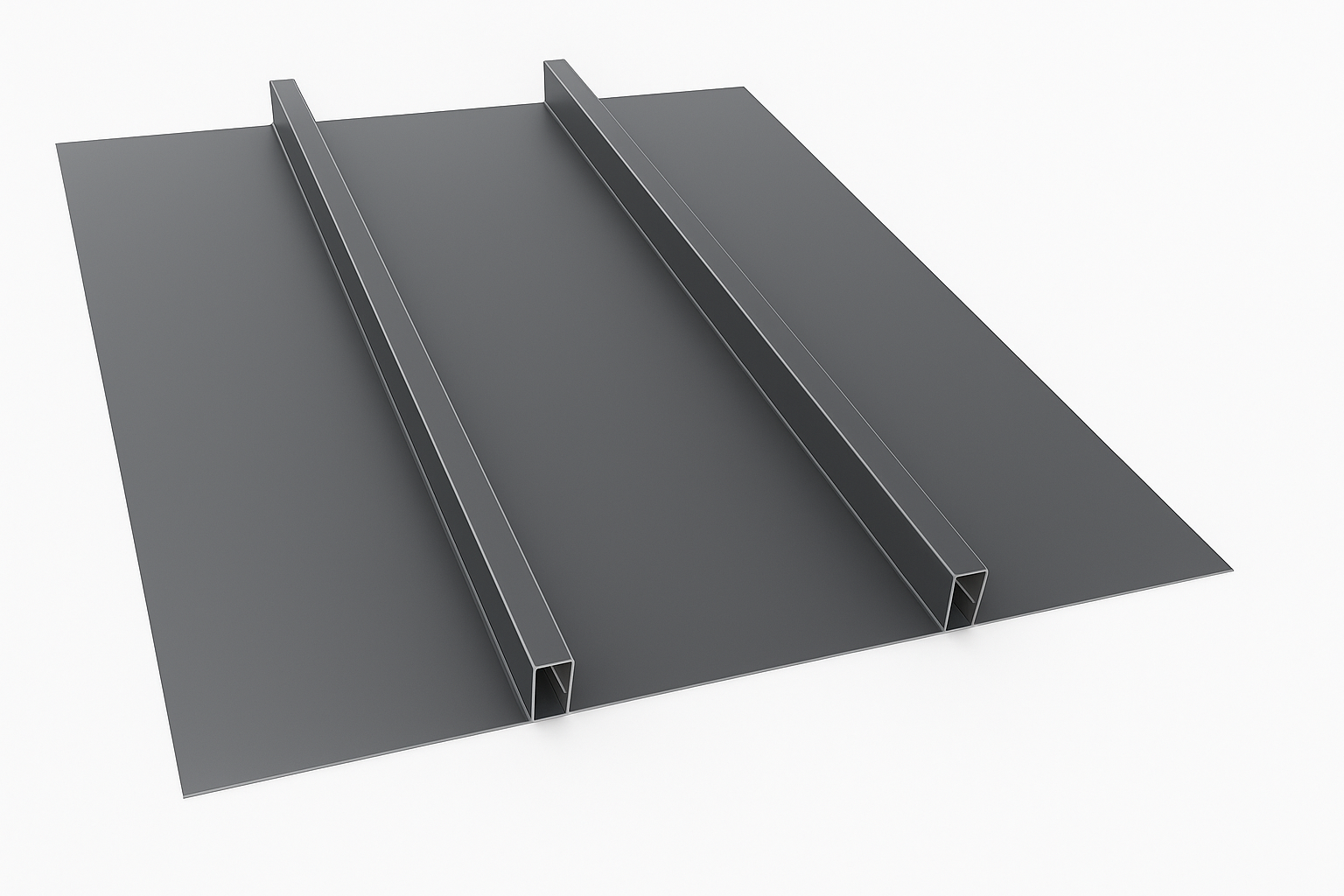

PAC T-250

PAC T-250 metal roof panels are engineered for low-slope applications and available in a variety of materials, including durable steel and aluminum. Featuring a concealed-fastener clip system, they accommodate thermal movement and require mechanical field seaming for a secure fit. Suitable for use over multiple substrates, installation includes a recommended underlayment for optimal performance. Seaming tools are supplied by D.I. Roof Seamers to ensure proper installation.

Features & Benefits

Standard is smooth panel

Maximum factory-produced panel length is 54 ft. (check w/factory for longer lengths)

Can be tapered and radiused; consult factory for limitations

Architectural/structural panel

Factory-applied sealant in seam cover

Continuous interlock

35-year non-prorated finish warranty

Weathertightness warranty available

Installation

PAC T-250 panels are intended for use in architectural and structural roofing. Substrates may include 5/8” min. plywood, nailboard insulation or equal with an underlayment of ice and water shield applied horizontally from eave to ridge. Other substrates may include metal decking, purlins or rigid insulation in conjunction with bearing plates. Contact Petersen for further assistance with installation details. For coastal applications, aluminum panels along with stainless steel clips must be used to qualify for warranty. Consult a local architect/engineer for compliance with local codes and conditions.

The T-250 panel is bi-directional, which allows installers to position the first panel in the center of a roof and install simultaneously in both directions, making it easy to achieve an attractive symmetrical look, while allowing multiple crews to work at the same time.

Pac metal roofing, wall, & trim catalog

Explore

Color charts

FAQ

-

Yes, see here forour color options.

-

Click here to learn more about IB Roof Systems

-

Chris Headley himself has over 22 years experience with construction materials such as PAC-Clad | Peterson products.

-

From Oklahoma City to Houston, and from Midland/Odessa to East Texas