Envelope 2000®

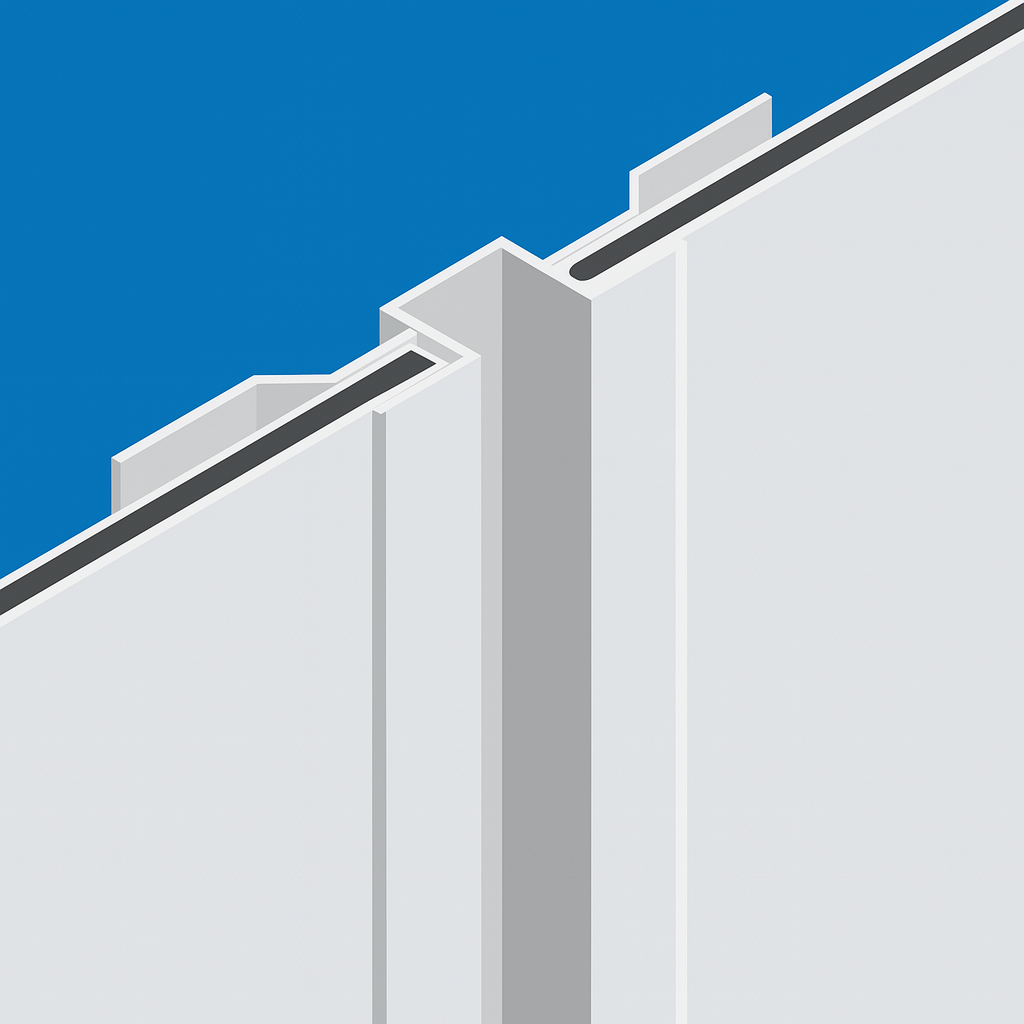

Reveal (RV) System

You get the trusted performance of ACM/MCM with the flexibility to fabricate right on-site—no long lead times, no overcomplication. These systems deliver high-end looks and high-level performance, with wet and dry sealed options to match your project’s specific needs. It’s value without compromise.

Features & Benefits

4mm Phenolic Resin Panel

Performance Testing for Panel and System

Fire, Impact, and Water Resistance

Panel and Finish Warranties

Low Maintenance with Quick Lead Time

FINISHES

Available in a variety of colors and finishes:

Smooth Kynar 500

Smooth Anodized

Complete

design guide

Explore

Color chart

resources & Information

Complete

design guide

Explore

Color chart

FAQ

-

Yes, see on our product pages for color options

-

Click here to learn more about IB Roof Systems

-

Chris Headley himself has over 22 years experience with construction metal and roofing materials such as PAC-Clad | Peterson products.

-

From Oklahoma City to Houston, and from Midland/Odessa to East Texas