Aluminum Composite Panels (ACM) — Lightweight Architecturally Versatile Composite Panels

What is ACM?

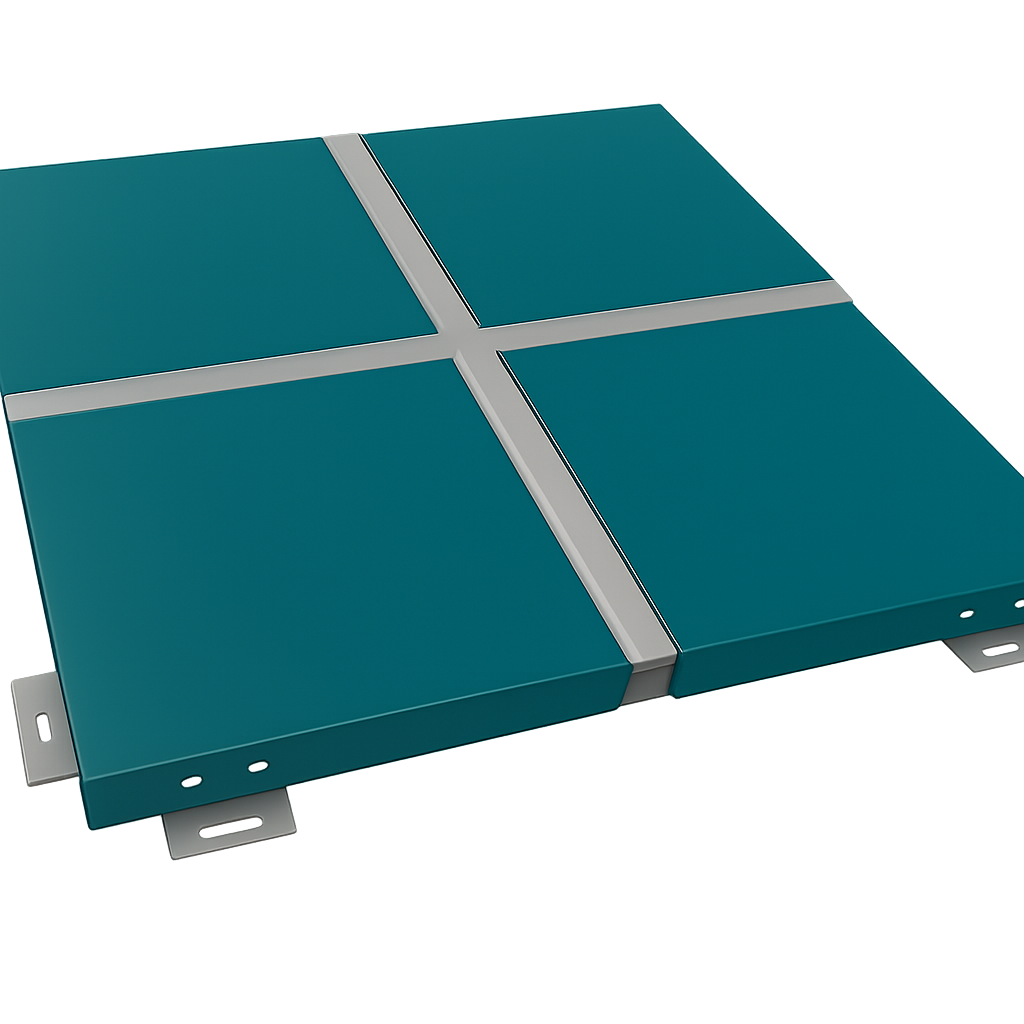

Aluminum Composite Material (ACM) consists of two thin aluminum sheets bonded to a solid polyethylene core, forming a lightweight yet rigid panel. Known for its exceptional flatness and durability, ACM is widely used in architectural facades, signage, wall cladding, partitions, and visual display elements. Available in multiple thicknesses—typically 3mm, 4mm, and 6mm—ACM panels provide the flexibility to meet a range of performance and aesthetic requirements across commercial and design-focused projects.

What materials and types define aluminium composite panels and metal cladding?

Aluminum Composite Panels pair aluminum faces with cores of polyethylene, mineral-filled core, or fire-rated compositions to meet specific performance criteria. Metal cladding panels use materials such as aluminum, Galvalume-coated steel, copper, or zinc, with cores or insulation layers when thermal control is required. Variations include:

Panels with polyethylene core for lightweight façades

Fire-rated ACM for high-rise and public buildings

Solid aluminum panels for rainscreens

Steel panels with Galvalume coating for durability

These material choices affect weight, fire performance, rigidity, and installation methods.

Aluminum Composite Panels for Advanced Facade Applications ...flammable materials into aluminum composite cladding panels and their widespread use [16,... lightweight composite formulations for advanced facade applications exhibiting superior performance...A Comprehensive Review of Aluminium Composite Panels: Current Research, Challenges, and Future Research Direction, MR Hasnat, 2025

How do metal cladding systems vary for architectural and commercial use?

Metal cladding systems differ by panel profile, joint type, and attachment method. Key categories include:

Standing seam panels with concealed fasteners for sleek rooflines

Interlocking wall panels that lock together for rainscreen assemblies

Exposed-fastener panels offering straightforward installation and cost efficiency

Each system balances aesthetics, thermal performance, and budget constraints to meet diverse architectural demands.

ALUMINUM COMPOSITE MATERIAL AVAILABLE ONLINE

Can you provide examples showcasing the versatility of PAC-CLAD panels in different climates?

PAC-CLAD stands up to Texas heat, Houston humidity, and Oklahoma hail through robust coatings and materials engineered for local conditions. Case studies include:

A Dallas-area campus with vertical precision series panels resisting UV degradation

A Houston medical facility using insulated panels for interior climate control

These installations demonstrate long-term performance across temperature extremes and moisture exposure, along with Class A fire resistance suitable for building code compliance.

How does PAC-CLAD ensure long-term performance through warranties and coatings?

PAC-CLAD’s 35-year finish warranties guarantee color and film integrity, backed by PVDF coatings with documented fade and chalk resistance. Substrate warranties protect against perforation and delamination, ensuring owners receive enduring protection and aesthetic consistency.

| Product Line | Key Feature | Application |

|---|---|---|

| Standing Seam Roof | Concealed fasteners | Commercial and industrial roofs |

| Precision Series HWP | High-profile ribbed walls | Vertical wall cladding |

| Modular AL Wall | Interlocking panel system | Customizable architectural façades |

| ACM Composite Panels | Aluminum composite construction | Signage, interior walls, exteriors |

Conclusion

Aluminium composite panels and metal cladding systems offer a perfect blend of durability, aesthetic appeal, and energy efficiency, making them ideal for modern construction projects. With PAC-CLAD’s extensive product offerings and CK Materials LLC’s expert support, architects and contractors can confidently navigate their material choices and project requirements. By choosing these innovative solutions, you can enhance your building's performance while contributing to sustainable practices. Discover how CK Materials LLC can assist you in specifying and procuring PAC-CLAD products for your next project today.

ACM – Frequently Asked Questions

ACM panels combine thin aluminum sheets with a lightweight polyethylene core, delivering strength and flatness at a fraction of the weight of traditional aluminum. This composite structure ensures panel rigidity and dimensional stability.

Yes—many ACM options are optimized for UV, latex, and screen printing or vinyl lamination, making them ideal for interior decoration and exterior applications.

Yes— PAC-CLAD offers Class A fire resistance suitable for building code compliance. This makes them an excellent choice for commercial buildings and areas where fire safety is a critical concern.

Always follow recommended blade/feed rates to maintain edge quality. The fabrication process is straightforward, allowing for easy installation and panel configuration in various designs.

There is no such thing as a "standard product". Everything is custom. Contact us with your specific ACM panel requirements for a free quote.

The only disadvantage I can think of is the price. This great quality doesn't come with a notably cheap cost.